Well, today is Ash Wednesday... the day all the revelers from the long weekend rise up out of the ashes into Lent. Not really, but it's a nice way to think about it. Here in South Louisiana we've just finished the Mardi Gras carnival season. Lafayette has one of the largest celebrations under New Orleans. Lundi Gras and Mardi Gras were not real big this year due to record low temperatures, 30 degrees until noon, and freezing rain on Fat Tuesday. It literally put a damper on the party. We haven't seen it that cold for Mardi Gras since 1986, AND Mardi Gras was later this year. The carnival made it difficult to get to the shop over the course of the 5 day weekend. The parades cut of the streets that I would travel to get there. I did play many gigs over the weekend and that was fun.

Early last week at LA Backbeat, I sent out orders for trials of prototype sticks. The reviews are coming back very positive. Feel, balance, playability came back good. Now it's time to work more n the aesthetics along with more tip design.

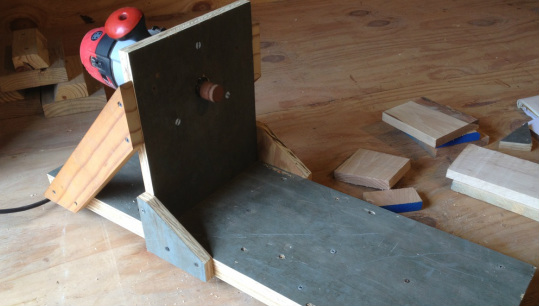

I ordered some components to do some fabrication on a tool for tips last week. They came in Tuesday and I went in today and spent 5 hours fabricating a tool to shape the ends. I thought I could use a hollowed out grinding stone in the router with some water to keep the hickory from burning. It worked, unfortunately it did not work that good. The hickory grinding made a horrible squeal like stepping on a cat's tail and took too long. Oh well, back to the drawing board. Looks like I'll be designing a tip chucker and having it machined.

Early last week at LA Backbeat, I sent out orders for trials of prototype sticks. The reviews are coming back very positive. Feel, balance, playability came back good. Now it's time to work more n the aesthetics along with more tip design.

I ordered some components to do some fabrication on a tool for tips last week. They came in Tuesday and I went in today and spent 5 hours fabricating a tool to shape the ends. I thought I could use a hollowed out grinding stone in the router with some water to keep the hickory from burning. It worked, unfortunately it did not work that good. The hickory grinding made a horrible squeal like stepping on a cat's tail and took too long. Oh well, back to the drawing board. Looks like I'll be designing a tip chucker and having it machined.

Last week also included a couple trips to the hardwood distributor. That was a challenge. They had not received any new hickory since I went through it the last time. I picked through a few hundred board feet to find about 80bf of fairly usable material. I spoke with the manager about my needs and he said he would get another pallet for me. They are finally getting to know me and what I am doing. I also picked up some very straight grain hard maple and some extremely nice pecan. I've been experimenting with pecan, turned several pair, and have received good reviews from the few drummers I've let try them. The drummers like the feel and the weight is a little less than hickory. The only thing I'm find is that the density of the wood varies tremendously in a single board. Hickory is much consistent throughout a board. I will continue to turn hickory even though supply is low on the south coast.

Sometime during last week I chopped and ripped all the boards into squares. It didn't take me that long. I'm getting very fast at chopping with the jig and developing a routine for ripping rather quickly while still being very safe. There is a little over 420 pieces of hickory, about 100 pieces each of maple and pecan. That's enough for about a run on sharp tooling.

I spent about two hours this afternoon sharpening the short straight knife and the tip/taper piece I've been using, along with cleaning up the long knife that had some waves in the straight and some imperfections from machine shop sharpening. That took the longest to do. I'm using all hand hones and had to take my time so not to take to much off in any one area. I also reground a gouge and sharpened the roughing knife and gouge. I received the last of the stones early this week too. All the tooling is VERY sharp now and ready for turning. I plan on turning Friday morning so I can put in a full run on the sharpened tooling. I've found that the tooling doesn't work well if used for short runs over a few days. My plan is to turn long runs until I need to sharpen, minimizing setup time for stick sizes and build stock that way too. It's all about time.

There will be more R&D of a tip shaper/chucker, a call into the wood distro to check on the hickory status and more work on the website and some bookkeeping POS work... all along with turning more sticks.

Wanted to make an update... it's been a while... I misplaced my hat.

Frank

Wanted to make an update... it's been a while... I misplaced my hat.

Frank

RSS Feed

RSS Feed