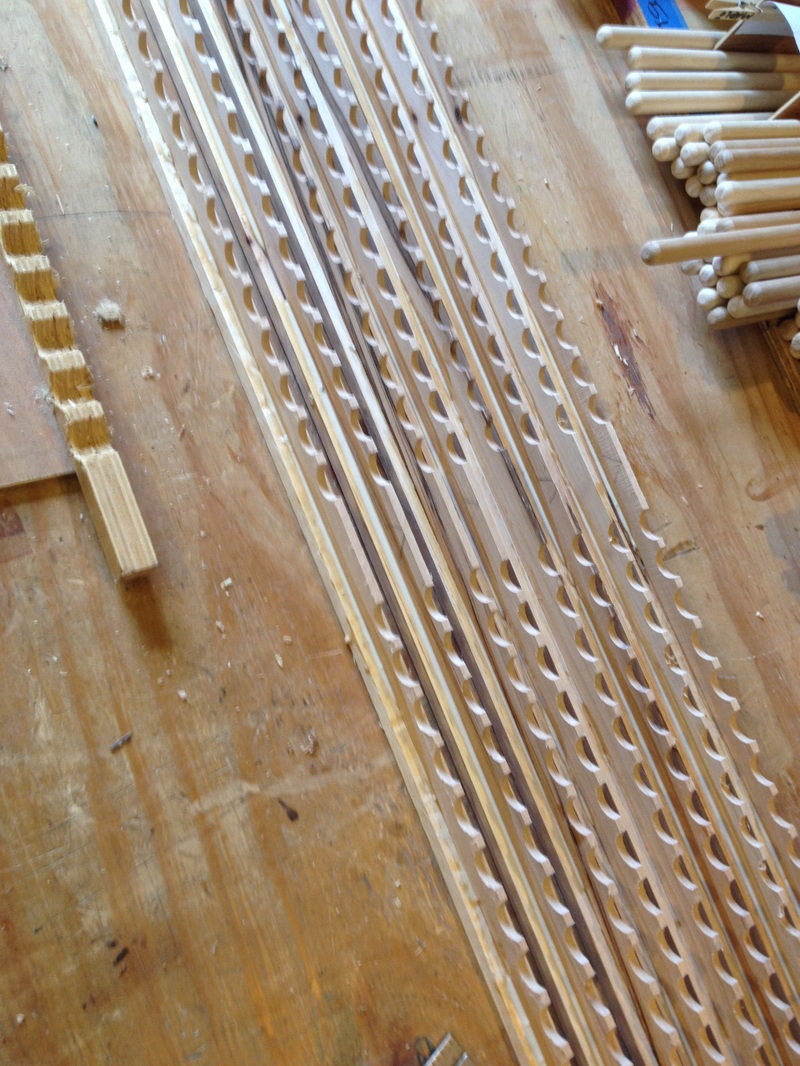

'nother good day t'day... went out to my friend Jason's Lullaby Sound Design launch party in the morn then back to the shop to turn, trim, tip and butt. Good day yesterday as well with my old friend Martin. He's picked up everything well, even the challenging finesse of the tipping jig.

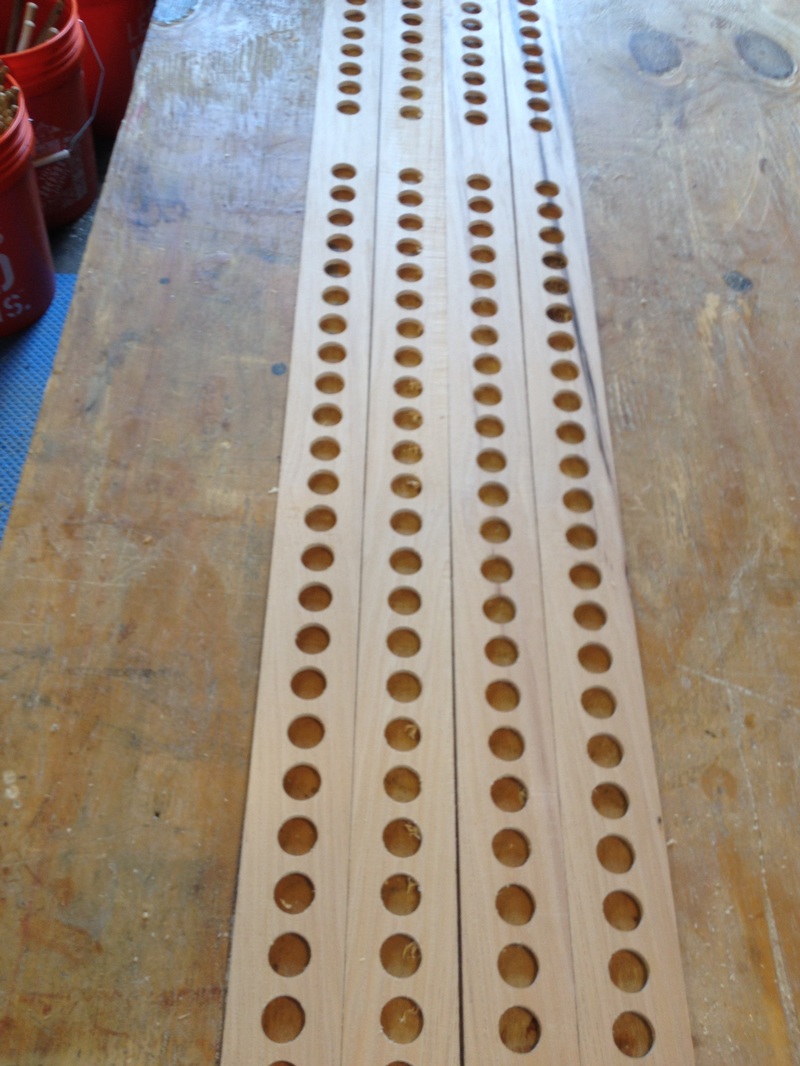

And, by the way, I got a lot of wood.

RSS Feed

RSS Feed